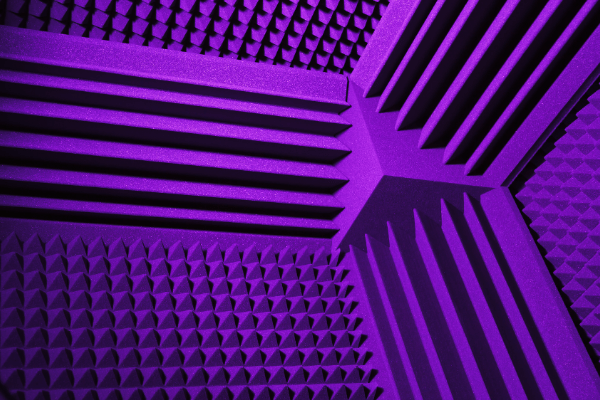

You probably know that the best bass traps are fiberglass, rock wool, cellulose, and acoustic foam. But how thick should they be in your room?

Bass traps should be 4 to 8 inches thick. However, the ideal depth may vary depending on your material density, placement, and desired frequency. Thicker sheets work better for larger bass traps, especially with lightly packed material. You can also use a thickness calculator for exact estimations.

In this article, we’ll show you how to calculate the best thickness for your bass trap, explaining the effective factors on your choice. We’ll also talk about bass traps vs. acoustic panels when it comes to thickness.

How Do Bass Traps Work?

Any given room has four walls which are two-by-two parallel. When the sound travels between these parallel surfaces, a kind of firm resonance will occur, which causes acoustic distortion and impedes authentic sound reproduction.

As a result, you may hear the bass notes very high in some spots and not hear at all in others.

When you put bass traps in a room or studio, you create a kind of friction between the sound vibrations and the solid surface of panels. This abrasion effect converts part of the sound energy to heat (think of when you rub two rocks together), causing the frequencies to drop.

So, you can hear a more accurate and closer sound to what’s coming out from the acoustic source.

What Is the Ideal Thickness for Bass Traps?

As a rule of thumb, your bass trap thickness should be no less than 4 inches. But the thicker it is, the more sound waves it can absorb. So, it’s best to make them up to 8 inches thick if you’re looking for maximum effectiveness.

For a DIY panel, start with the minimum thickness, and cover all the corners. If you still have more material, start adding more layers. You can also test the efficiency of your bass traps at 4-inches deep and thicken them if needed.

That said, you can’t tell the exact ideal bass trap thickness without considering other factors, especially your room conditions.

Depending on your material density, placement, and desired frequency range, you may need different thicknesses. Below, we’ll discuss each element in detail and how it can affect your decision.

Targeted Frequency Range

In theory, the thicker a bass trap, the lower frequency it’ll catch. So, if you usually deal with longer wavelengths and want to trap deeper bass noise, thicker is better for you.

For example, 2-inch absorbers can’t make your frequency sounds lower than 300Hz, while four-inch ones decrease them down to 100Hz. And as the most efficient ones, 8-inch bass traps give you a remarkable performance down to 70 Hz.

However, that’s only an observational guess. For more accurate estimations, you can calculate your desired thickness by the quarter wavelength principle. Based on this formula, your panel’s thickness should be about ¼ your required wavelength.

So, if you want to target the 100Hz frequency, this is what you should do:

- Frequency = Wave Speed / wavelength. You have to divide the “Speed of sound” by the frequency to get the wavelength (1300/100=11.3 feet). Note: The speed of sound is about 1300 km/h at room temperature.

- Multiply the result by 12 to convert the value to inches (11.3×12=135.6 inches).

- Divide it by four to get the ideal thickness (135.6/4=33.9 inches).

- Since acoustic signals hit the absorber at various angles instead of a vertical direction, you should divide the previous value by two to make up for the potential error (33.9/2=17).

So, you’ll need about 17 inches in thickness to reach as low as 100Hz.

Important: You may ask, how can you get a bass trap with that thickness while the ones in the market are only a few inches?

Here’s the answer: Bass trap manufacturers compensate for this lack of thickness with material density. And that’s because fitting a few feet of bass traps in a small studio isn’t practical.

Panel Placement

To get the most out of your insulation thickness, you also need to consider the wall-to-panel distance. A helpful trick is to even up the thickness with your spacing. It means, if you decide to leave a four-inch gap between the wall and your panel, you’ll need four inches of insulation.

That’s because having a bigger gap than depth may lead to diminishing results. Besides, proper spacing helps you catch the most absorption with the minimum amount of material.

Interestingly, not every spot needs the same thickness. Corner bass traps work better at 4 inches depth. But if you want to mount them on a flat surface, namely, the front wall, you’d better condense them up to six inches.

Material

Type

Even if you use as thick as 10-inch bass traps, you can never be sure that they work unless you know what they’re made of. Perfect sound absorption is a combination of factors, and your insulation material matters more than the thickness.

For example, porous absorbers such as fiberglass, Rockwool, and acoustic foam can’t trap the lowest bass notes unless they’re super-thick. So, if you’re using these materials, go for a thicker diameter than what you’ve calculated.

Resonant absorbers, on the other hand, have superior bass coverage. Therefore, you don’t have to make them very thick. Helmholtz and Diaphragmatic absorbers belong to this group.

Density

Density refers to how tightly the absorbent fibers are woven together. The denser the fibers, the fewer air particles can pass through it, and the better it absorbs the notes.

If you happen to use lighter material, you can compensate for its performance by making it thicker. But sometimes, you’ll need dozens of inches, and that requires plenty of physical space. And nobody wants to lose space while they can get the job done by increasing the density of the material.

Ideally, match four-inch insulations with 60-75kg/m3 sheets. And consider eight inches of depth if it’s 45kg/m3 dense. Any less than 36 kg/m3 requires you to go up to two feet deep.

If you’re using fiberglass 700 Series Insulations, this table helps you find the best density-to-depth ratio.

Note: X kg/m3 products from one manufacturer may produce different outputs than another company’s products. So, make sure you’re buying from a reliable producer with standard measures.

Don’t Confuse Bass Traps With Acoustic Panels

Acoustic panels and bass traps aren’t the same. While bass traps take care of longer wavelengths (low-frequency sounds), acoustic panels can address the higher end (mid to treble frequencies with short wavelengths).

That’s why they come with different thicknesses. Acoustic panels are normally two inches thick, and that’s sufficient to achieve their intended results. But bass traps should be far deeper. In some cases, they can be as thick as a few feet.

The reason is, lower frequencies are far more difficult to tame due to their longer wavelengths.

Many online tools such as AcousticModeling help you deal with the details.

All you need is to measure and enter a few parameters, including the frequency range, air temperature, pressure, incidence angle, and absorbent model. Then, the tool will give you the absorbent’s coefficients.

Conclusion

Your bass trap thickness depends on many factors, e.g., your material type and density, where you will place them, and how much absorption you need.

But overall, you have three options to guess the thickness level:

- Calculate your desired thickness using the “¼ wavelength rule” and “wavelength= Wave Speed / Frequency formula.”

- Consider using a thick material as the air gap between the wall and the panel.

- Go as thick as you can for lighter material, and do the opposite for denser ones.

- Take advantage of the ready-to-use measurement tools.

Sources

- Primacoustic: Bass problems in the studio

- Soundproof Central: A Complete Guide To DIY Acoustic Panels And Bass Traps

- The Home Theater DIY: Acoustic Panel Sizing Guide – How Big Should They Be?

- Acoustics Insider: The Best (And Only) Insulation Material You Need For DIY Acoustic Absorbers

- E-Home Recording Studio: The Ultimate Guide to Bass Traps for Home Recording

- Gearslutz: 4″ Thick Bass Traps vs. 6″

- Buy Insulation Products: DIY BASS TRAP GUIDE

Recent Posts

QuickTime is a vital app for many Mac users, and if you’ve recently bought a new microphone, you might wonder how to use it optimally. QuickTime cannot record audio content if it doesn’t have...

Every microphone leaves a unique signature on the quality of its output. If you’re a podcaster trying to melt your way into your audience’s hearts, a muddy, distorted recording won’t cut it....