There are environments where sound quality is of the utmost importance. Whether it’s the space where you watch the latest Netflix series, host your Friday night parties, or record your musical masterpieces, the sound shouldn’t echo or vibrate. If you find yourself looking to optimize the sound quality of a room, the choice of foam is an essential consideration.

Acoustic foam is firmer, more durable, has higher levels of fire resistance, and has a different structural composition. Ultimately, acoustic foam is a more specialized and tailored product designed for a small set of specific use cases.

In the remainder of this article, I’ll offer an in-depth explanation of the differences between acoustic and regular foams and the potential downstream implications of these differences. You can use this information to make a sound decision about which type might be best for you.

Acoustic Foam vs. Regular Foam

For anyone who’s not an expert on sound-blocking foams, you’d be forgiven for thinking that acoustic and regular foam are essentially the same thing. However, these two foams have several crucial differences that impact their performance, durability, and cost.

The table below summarizes these critical differences and can help you familiarize yourself with the dissimilarities between acoustic foam and regular foam.

| Aspect | Acoustic Foam | Regular Foam |

| Firmness | Optimized for absorbing specific sound frequencies. Typically denser than standard foam products. | Not constructed with sound absorption in mind. Often more lightweight and pliable than acoustic foams. |

| Durability | Constructed from a resilient material that can withstand minor accidents. | Less durable and more prone to degradation over time, especially when exposed to moisture. |

| Fire resistance | Must comply with regulatory standards relating to fire resistance. | Not designed with fire resistance in mind. |

| Structural composition | This foam is typically made of dense polyurethane or extruded melamine. | This foam is often made of thin viscoelastic polyurethane or polyester. |

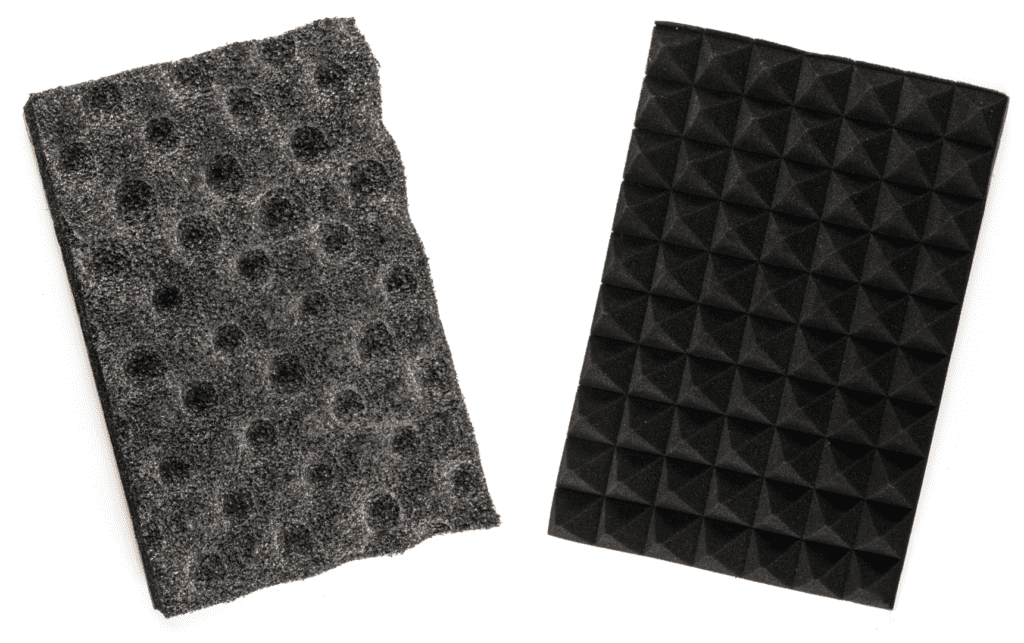

| Appearance | Inexpensive options may have an egg-crate texture, while pricier options tend to utilize a multi-bar texture. Almost always dark in color. | Typically light-colored, with a flat or dimpled texture. Appearance varies greatly. |

| Cost | A specialized product that commands a high price tag. | A widely available and relatively inexpensive material. |

I’ll now explain each of these differences in greater detail.

Firmness

Firmness is probably the main differentiating factor between acoustic and regular foam. Acoustic foam is made of an extremely soft and porous material, which absorbs sound waves instead of reverberating them throughout the room.

It has this ability because it converts sound energy into heat using the law of the conservation of mass. This heat then dissipates into the surrounding environment.

A scientific measurement known as the Indentation Load Deflection (ILD) describes the firmness of a foam material. In a nutshell, foams with a higher ILD will absorb more sounds of a lower frequency, while foams with a lower ILD will absorb higher frequency sounds.

The highest quality acoustic foam achieves the optimal compromise between these two attributes, absorbing sounds that fall within both frequency ranges.

On the other hand, standard foams tend to be breathable and soft. These allow them to be malleable enough for use as mattress toppers, pillows, and cushions. Regular foam’s low density also contributes to its durability.

Thicker foams can retain moisture, increasing their risk of developing mold and decomposing. That said, dense melamine acoustic foams aren’t at risk of rapid decomposition or mold growth.

Durability

Given its purpose, acoustic foams must be a tough and resilient material. Music studios and recording rooms are characterized by commotion and many people moving around.

Therefore, the foam will be subject to various stresses. So, it makes perfect sense that acoustic foam would have to be composed of durable material.

Acoustic foam is a ‘non-dusting’ material. In layman’s terms, it won’t decompose, and it won’t produce tiny little fragments of foam every time you rub off against it. These features make it a desirable material for recording studios of all sizes.

Decomposition doesn’t typically pose a significant problem for regular foam’s regular applications, like being in a pillow. Additionally, thin standard foam sheets are easy to wash and dry, helping prevent long-term bacterial and mold growth. However, this type of foam isn’t acceptable in a recording environment, as it can begin to fall apart after multiple washes or contact with fabrics.

Fire Resistance

Granted, this may not be the first metric that springs to mind when assessing the relative merits of different types of foam. However, accidents happen occasionally, especially in recording studios, where the large volume of electrical equipment in a confined space could become a fire hazard.

Therefore, there are fire retardancy standards that acoustic foam must meet. More specifically, acoustic foam must undergo the industry-standard ASTM E84 burning test.

The ASTM E84 assesses the fire retardancy of construction materials. Class A products demonstrate the highest ability to withstand fire. As a result, acoustic foams are designed to resist high temperatures and flames.

But unlike acoustic foam, which is primarily used in recording studios, regular foam has a variety of uses and applications. For this reason, not all standard foams are flame-retardant. They can quickly catch fire and spread flames throughout a room.

Structural Composition

The differences between acoustic foam and regular foam can be traced back to their molecular structures.

Every material in our daily lives is composed of millions of molecules/particles. The volume of these molecules, coupled with how they’re arranged around one another, gives materials their intrinsic properties.

When talking about foam, the most significant structural composition attribute is Pores Per Inch (PPI), which measures the number of molecules in a linear inch of the foam. As a rule of thumb, foams with a higher PPI have a greater ability to absorb sound than those with a lower PPI.

When observing acoustic foam with an electron microscope, you’ll see a honeycomb structure that’s primarily made of empty open cells. These cells are pores, small openings that trap heat and sound.

But if you were to place regular polyurethane foam onto a slide and view it at a microscopic level, you’d find far fewer pores. The structural composition of standard foams is far thicker and tighter, causing the material to bounce sound back instead of absorbing it.

Appearance

While some customers may dismiss this as a trivial aside, aesthetics is critical for many others.

Not much consideration is given to conventional foam’s visual appeal because it’s invariably going to be concealed for almost all of its life. For example, take a foam pillow. We don’t care if there’s a blemish or pattern irregularity on it because it’ll be beneath a pillow cover anyway.

This is in contrast to acoustic foam, which will spend most of its life cycle in plain view.

Since acoustic foam is used in creative environments, such as a recording studio, customers are quite specific about the color and shape of the material. To cater to these demands, acoustic foam is manufactured with aesthetic components as a consideration.

Consequently, acoustic foam is almost always easier on the eyes than conventional foam. It’s also worth noting that nearly all acoustic foams are black or gray, making them a neutral hue that pairs well with every color scheme. Regular foams are available in a wide variety of colors, making them far more challenging to match to pre-existing decor.

In addition, manufacturing standards and quality checks are usually much more rigorous for acoustic foam. Acoustic foam is often installed in a room in a modular fashion, i.e., piece by piece.

This design feature allows users to add additional pieces of acoustic foam while maintaining a high level of aesthetic appeal. The same cannot be said for standard foams, which easily discolor due to prolonged exposure to UV rays, sweat, bacteria, mold, and spilled beverages.

Cost

Thus far, I’ve stated that acoustic foam is preferable to conventional foam across all metrics above. However, you may not be surprised to learn that there’s a price to be paid for this superior performance and utility.

More often than not, acoustic foam is considerably more expensive than regular foam. It’s a costly commodity full stop. Many people tend to be very surprised when faced with the cost of acoustic foam. After all, it’s still just foam at the end of the day, right?

As mentioned earlier, acoustic foam’s superior capacity to absorb sound waves is because of its cellular structure. As a result, manufacturing it at scale takes longer and requires more personnel.

In addition, optimizing the material for sound absorption involves a lot of manual manipulation. This higher cost of production contributes to its final retail price. To provide some context, the current price estimate for a four-inch (10.16 cm) acoustic foam panel is between $200 and $220.

Another reason acoustic foam is more expensive is that it’s a niche product. People primarily use acoustic foam to keep recording studios soundproof, and there are few additional applications.

On the other hand, conventional foam has a variety of uses. It also features a molecular structure and composition that requires far less manual labor, resulting in reduced manufacturing costs. As such, regular foam is comparatively cheap when compared to acoustic foam.

Which Should I Buy?

To decide between regular and acoustic foam, you need to consider two things: your use case and your budget. Go for regular foam if you intend to use the foam for anything other than maximizing sound quality. However, acoustic foam is the superior option if sound quality is your primary concern.

Acoustic foam is always the better option to block sounds from other rooms or outdoor environments. It can also help keep sound contained, preventing you from driving your neighbors or roommates crazy while loudly practicing or recording music.

For this reason, you should buy acoustic foam if attempting to control sound within a specific room or area.

But if you’re planning a crafts project that utilizes a general type of foam, you’ll likely want to choose standard foam. Regular foam is a fantastic material when creating pillows, quilts, plushies, and other common crafts. It’s also far more affordable than acoustic foam.

Is It Hard To Acquire Acoustic Foam?

It’s not hard to acquire acoustic foam. Music stores stock them because music producers use them for their studios. Also, some companies specialize in the supply of acoustic foam, and it’s also available through some construction supply stores.

You may want to visit your local music store to see if they have acoustic foam panels available. If they don’t, be sure to consider other in-store options and online retailers.

Where Can I Buy Acoustic Foam?

You can buy acoustic foam online and in-store from various retailers, including Amazon, Walmart, and Home Depot. You can also choose to purchase acoustic foam panels and sheets from retailers that specialize in manufacturing and selling sound-blocking products.

Many nationwide retailers sell acoustic foam in-store and online. If your local music store doesn’t sell acoustic foam, be sure to check your local department and home improvement stores. Should you fail to find acoustic foam from these retailers, your next best option is shopping online.

Amazon carries a variety of acoustic foam panels and sheets. For example, Audiosoul Acoustic Panels are a popular choice thanks to their sound absorbency and aesthetically-pleasing design. Amazon also ships products both domestically and internationally. This makes them one of the most accessible online retailers.

- ★ Professional Sound Absorbing Properties - Acoustic foams are installed to reduce noise pollution...

- ★ Quality - Our Acoustic Foam Panels are made with flexible, professional grade acoustic foam,...

- ★ More Comfort/Less Stress - The most common problem in large rooms with high ceilings is that of...

Last update on 2025-07-11 / Affiliate links / Images from Amazon Product Advertising API

However, you can also choose to purchase online from smaller retailers like Acoustical Solutions. This company sells acoustic panels, fabrics, and foams. They also offer a variety of soundproofing materials for windows, doors, ceilings, and floors. As such, they’re a top-notch retailer for those looking to soundproof a recording studio.

Final Thoughts

While acoustic foam and regular foam look and feel similar, there are several important differences between them.

Acoustic foam exhibits superior performance to regular foam in improving the sound quality across every conceivable metric. Due to the material’s structural composition, it has much better sound absorption properties than regular foam. It’s also much more durable because it tends to be installed where people and/or equipment are constantly on the move.

The one major drawback associated with acoustic foam is that it’s expensive and may be out of reach to somebody operating on a tight budget.

Sources

- The Sleep Judge: Indentation Load Deflection: A Complete Guide

- Oeler Industries Inc.: Acoustic Foam Panels

- ASTM International: Standard test Method for Surface Burning Characteristics of Building Materials

- The Foam Factory: The Differences between Conventional and Acoustical Foam

- Home Studio Expert: Why is Acoustic Foam So Expensive?

- Amazon: audiosoul Acoustic Panels

- Acoustical Solutions: Acoustic Panels

Recent Posts

QuickTime is a vital app for many Mac users, and if you’ve recently bought a new microphone, you might wonder how to use it optimally. QuickTime cannot record audio content if it doesn’t have...

Every microphone leaves a unique signature on the quality of its output. If you’re a podcaster trying to melt your way into your audience’s hearts, a muddy, distorted recording won’t cut it....